InVoyage™ + InControl™ = inTank™

How It Works

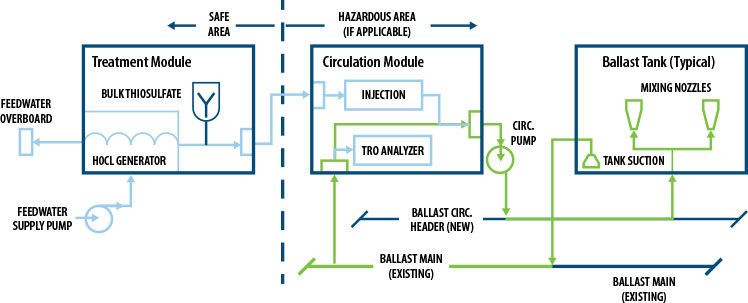

The Scienco Fast inTankTM BWTS utilizes salt water and Electrochemical Activation (ECA) to generate Sodium Hypochlorite (NaOCl) as the active substance to achieve ballast water discharge standards. The circulation module mixes one tank at a time where ballast water quality is assessed and the generated disinfectant is applied until the target Total Residual Oxidant (TRO) level is reached. The Scienco Fast inTankTM BWTS is effective in all water types including fresh, brackish, and marine water.

The circulated ballast water is returned through the patented in-tank nozzle mixing system that ensures even chemical distribution (see figure below). After an initial hold time, the circulation module rechecks the TRO in each tank, applying more NaOCl if required. This is repeated for all ballast tanks that require treatment. Prior to discharge, the circulation module checks the remaining TRO in the ballast tanks and applies Sodium Thiosulfate to neutralize any remaining active substance.

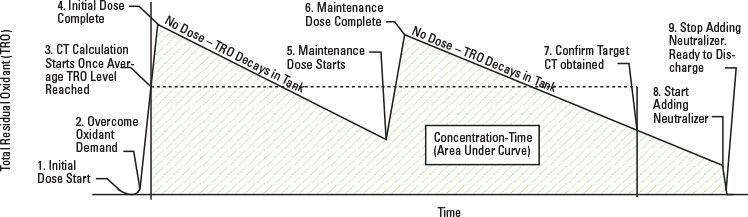

The inTankTM BWTS does not filter the ballast water on uptake, which is different than most in-line systems. To ensure consistent and effective kill of target organisms and pathogens, the Concentration-Time (CT) treatment approach is utilized. The recirculation capacity enables monitoring and re-dosing to meet the target combination of oxidant dose and hold time. The ability to dose in-tank and re-dose ensures effective treatment regardless of organic and inorganic loads in the ballast water.

Treatment Overview

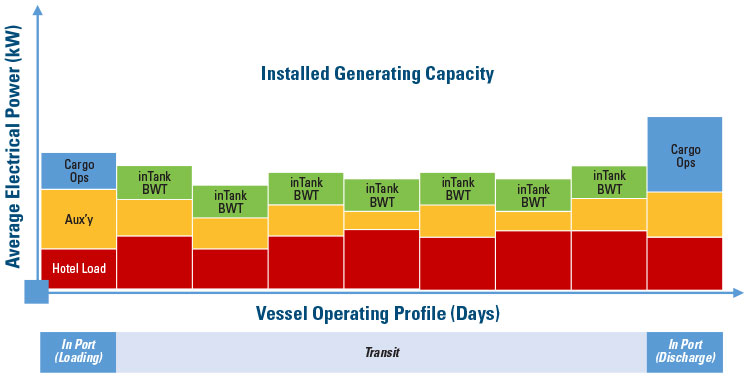

When a vessel uses the inTank™ BWTS, water is taken-up into ballast tanks with no change to existing operating procedures, i.e. no treatment occurs during uptake. A small portion of ballast water is suctioned from one ballast water tank at a time, passed through the circulation module, and returned to the same ballast water tank through in-tank mixing nozzles. Since the treatment process occurs during voyage, more power is available for the system. In most cases, no changes to shipboard power is necessary.

CT/Dosing

The inTankTM BWTS process ensures disinfection of ballast water tanks and piping through the application of a targeted CT, which is the product of disinfection Concentration (in milligrams per liter, mg/L) and disinfection contact Time (in hours) measured as total residual oxidant (TRO). The CT approach is commonly employed in the wastewater treatment industry and for municipalities ensuring safe drinking water.

The US Environmental Protection Agency (EPA) provides detailed guidance on CT calculation and application in its Disinfection Profiling and Benchmarking Guidance Manual. Scienco Fast has found that the effective CT for ballast water is an order of magnitude greater than that required to meet EPA drinking water standards.

Diffusion

The inTank™ mixing system was studied at full-scale with tracer dyes and in computer simulations for all tank confi gurations. The EPA manual (US EPA 1999b) provides guidance on assigning a “baffling factor” based on a tank’s mixing effi ciency. This factor accounts for dead zones and short circuiting of disinfectant application within a tank. Each inTankTMsystem will be engineered to meet or exceed EPA baffling factors to guarantee compliance.

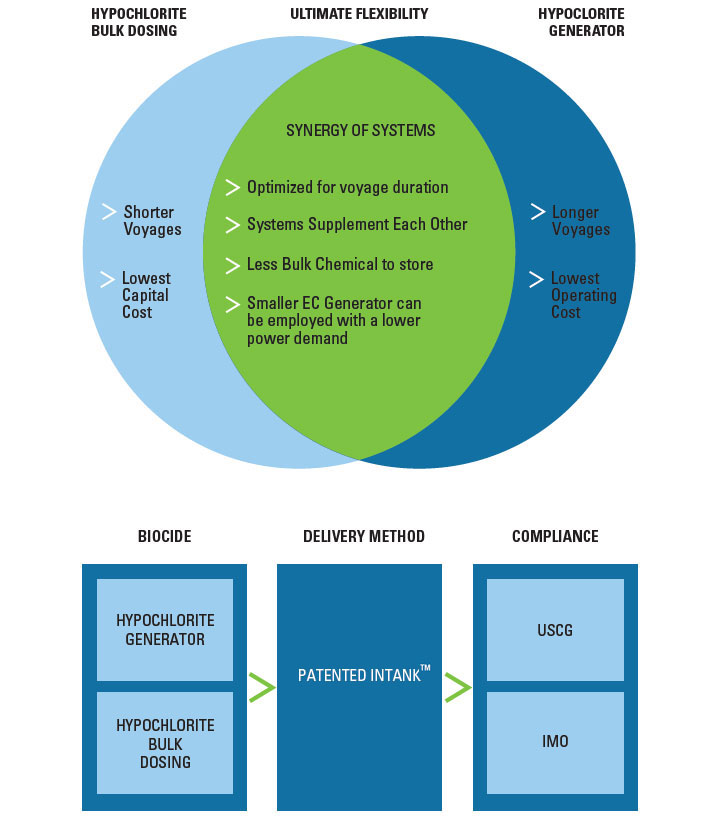

One System/Two Options

The primary advantage of the Scienco Fast inTankTM system is its superior method of chemical delivery. Our patented nozzle, coupled with an inTankTM distribution piping system is able to treat each ballast tank individually by distributing the active ingredient, sodium hypochlorite (NaOCl). Scienco Fast offers multiple options to produce NaOCl: bulk dosing and an onboard, electrochlorination generator. If the bulk-dosing option is selected, the user will simply maintain an adequate level of liquid NaOCl in a bulk-dosing tank. The system then distributes the chemical as needed when the ballast water treating cycle begins. In cases where the owner or operator chooses an on-site generator, seawater from the sea-chest is used to produce NaOCl that is similarly distributed to the ballast tanks. Both means provide a safe and reliable method to deliver the active substance into the ballast tank and ensure a compliant discharge. Regardless of the production method, the chemistry and biological efficacy are identical thus giving the ship owner the ability to choose the most economical method based on vessel ballast capacity and expected voyage time. This is a feature no other system can off er to the industry.